HOW THE SAFETY OF OUR E-BIKES IS ENSURED THROUGH COMPREHENSIVE TESTING

E-bike safety

Updated on October 27, 2023

Whether you use our electric bikes to transport your most precious cargo – such as your children – or simply for your own enjoyment, your safety is important to us. We firmly believe that e-bikes all over the world must meet high safety standards to ensure that they are fit for purpose. Even though it is important for us to build cool and versatile bikes, the safety of our products is our top priority.

In this article, you will find comprehensive information on how we subject our cargo bikes, which are also designed for transporting children, to rigorous testing. This is done with the aim of ensuring that they are consistently safe and reliable up to the maximum specified load limit.

DEVELOPMENT PROCESS OF THE FOLD LOAD WHEEL

During the development process of the Fold, the first fully-fledged foldable cargo bike, we attached great importance to defining a specific load limit. This included the maximum total weight of the bike, the weight of the rider and the conditions of use of the bike.

Load limit of the Fold

The load limit of the Fold is essential for its performance and safety. This has been defined as follows:

- Permissible total weight (GVW): 200 kg or approx. 440 Ib. This includes the weight of the bicycle, the rider, any passengers and all accessories and luggage.

Test and development process

To ensure the robustness of the Fold, it underwent a series of tests and development phases:

Internal load tests: The first prototypes were load-tested in the factory to ensure that they met the specified requirements. Several rounds of tests were carried out to rule out unintentional opening while driving.

A year in daily use: The working prototype was tested daily on long routes for a whole year, with many different riders. This feedback helped to further improve the design.

Development of the second prototypes: Based on the one-year practical test and feedback from hundreds of test riders, we were able to improve the original concept and test the user-friendliness.

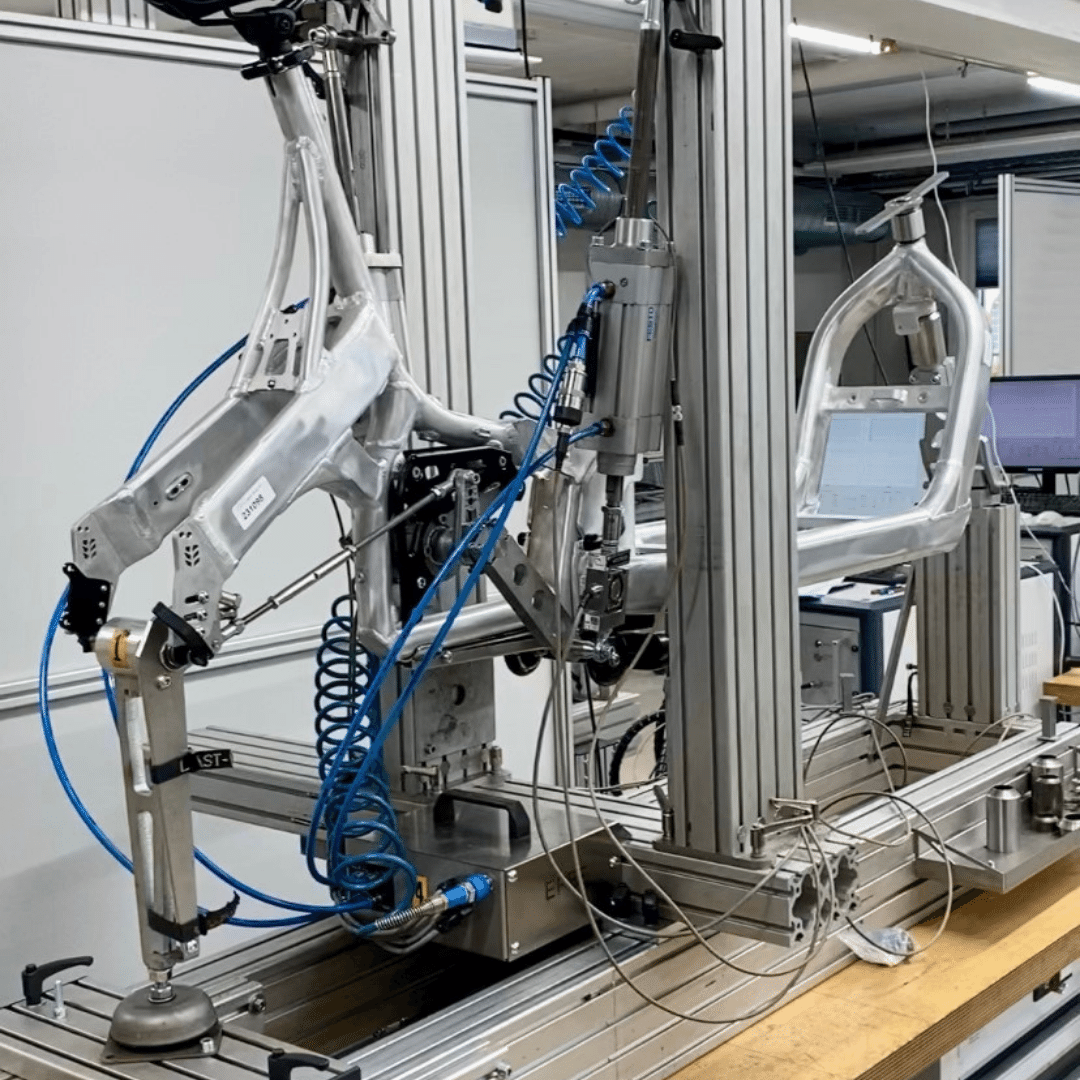

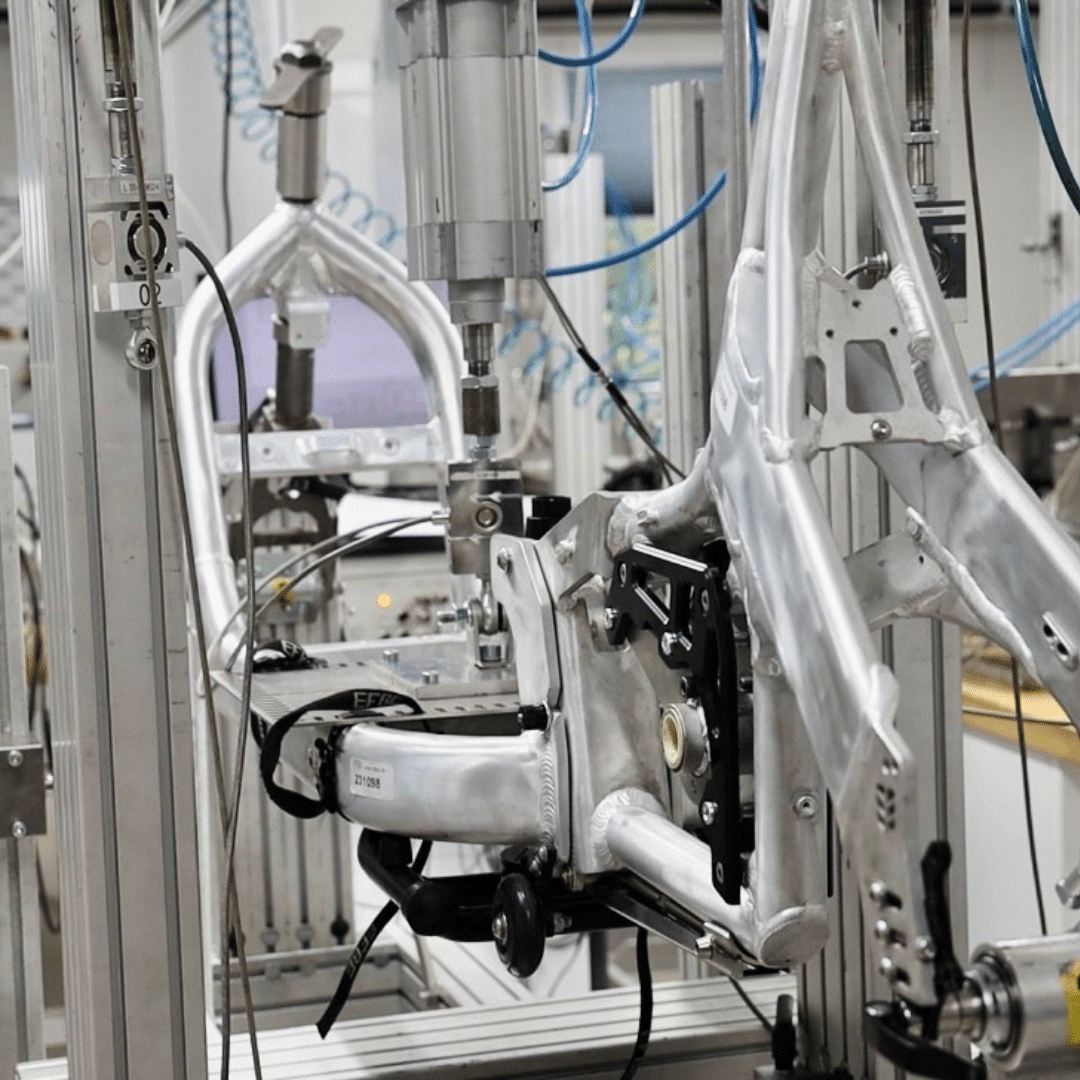

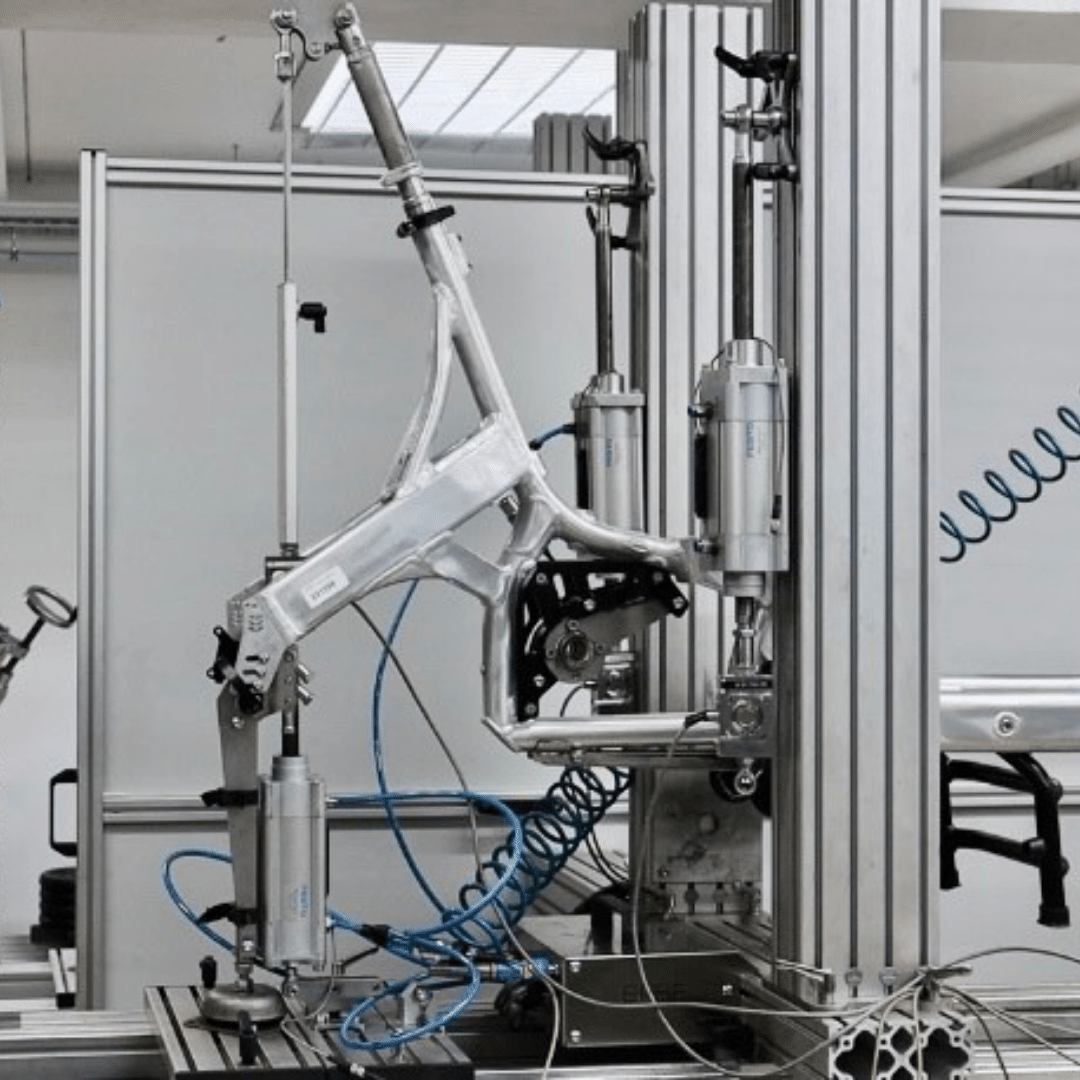

Pre-series frame tests at EFBE Prüftechnik GmbH: The pre-series frame was finally sent to EFBE Prüftechnik GmbH, a global market leader in the field of durability testing for bicycles. Here, the frame and forks were subjected to extreme load tests with hundreds of thousands of cycles under multidirectional load.

EFBE-TESTS

A Fold frame undergoes tests at EFBE.

At EFBE, the frame and fork undergo intensive testing in which hundreds of thousands of load cycles are simulated from various directions. The test procedure specially developed by EFBE, the Tri-Test, ensures that these parts are really tested to their maximum load limits. The EFBE Tri-Test is based on the current German standard DIN 79010:2020-02, 5.9.3 for transport and cargo bicycles, which enables a comprehensive and specific assessment of these vehicles. This standard was developed to take into account the special requirements of cargo bikes compared to conventional city bikes and aims to ensure their safety and reliability even under heavy loads. It makes explicit reference to the specified load, weight and geometry of a cargo bike. This targeted and thorough testing ensures that the cargo bikes function perfectly even under extreme conditions.

With a folding cargo bike like the Fold, it is particularly important that the folding mechanism also works perfectly under extreme conditions and does not open unintentionally.

The Tri-Test confirmed the above-average durability of the Fold: the bike withstood loads far in excess of the permissible gross vehicle weight (GVW).

This test procedure confirms the robust construction and demonstrates the reliability of the folding mechanism, making the Fold an exceptionally stable and safe cargo bike.

WHY IS THE EFBE TRI-TEST A CHALLENGING TEST?

The European EN standard for city and trekking bikes sets uniform test requirements for all conventional city bikes without adapting them to different areas of use. However, cargo bikes that transport heavier loads exert increased and modified forces on the bicycle frame and fork. The German standard for cargo bikes takes this into account and requires test forces that are proportional to the total weight of the system (bike plus rider, cargo and possible passengers).

Against this background, EFBE’s Tri-Test, which is based on the German standard, proves to be significantly more demanding than the tests for conventional city bikes. The Tri-Test includes eight intensive load tests, the forces of which are related to the maximum load capacity of the bicycle. One and the same bicycle frame must pass all eight tests, with any damage to the frame or fork caused by one of the tests being transferred to the subsequent tests.

Our in-depth knowledge of the intensity and procedure of the tri-test process enables us to say with certainty that our bikes are optimally matched to their intended use.